In today's society, where customers are more concerned about food safety due to incidents of food mislabeling and foreign material contamination, OGINOYA has been highly concerned about food safety for several decades and has introduced a thorough hygiene management system based on the concept of "cleanliness" to maintain a beautiful and hygienic environment.

Pulax, a disinfectant solution that has now become commonplaceIn 2002, we applied the concept of HACCP, an international hygiene management standard, and reviewed all 161 production processes. We promise to provide "safe and secure" products.

Careful hand washing

Hand washing and disinfection is performed every 30 minutes to ensure hygiene at all times.

Production line cleaning

At least six times a day. The production line is stopped and carefully cleaned.

jet air

Jet air is applied to the entire body to remove dust and debris from clothing.

Check heating conditions

The temperature is thoroughly controlled to ensure that cooked ingredients and rice are adequately heated.

Sterilization lamp (ozone generation)

Ozone-generating sterilization lights are installed throughout the plant. This eliminates odors.

Sterilization lamp (ultraviolet light)

UV sterilization lights are installed throughout the plant. This reduces the number of bacteria that fall out.

Steam cleaning of lids

Before use, kiln containers and lids are sterilized by washing with steam at 85°C.

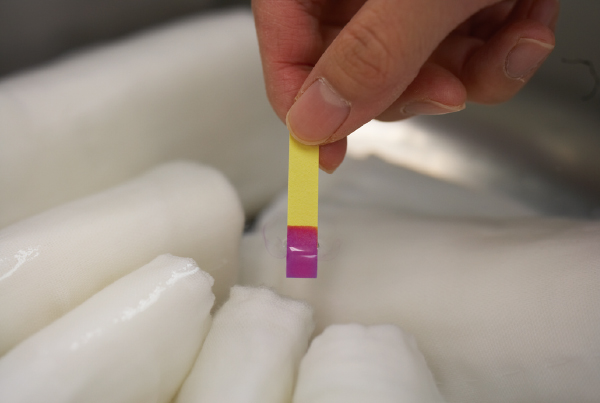

Check disinfectant solution

Disinfectant solution is changed approximately every two hours. The concentration is checked, and if it is cloudy, it is replaced immediately.

Awards and Recognitions

| 1957 | Yokokawa Manufacturing Plant | Received the Minister of Health and Welfare Award | |

| 1994 | Suwa Branch | Received the Nagano Prefecture Governor's Award for Excellence in Sanitation Facilities | |

| 1999 | Suwa Manufacturing Plant | Received the Minister of Health, Labor and Welfare Award | |

| 2009 | Yokokawa Manufacturing Plant | Received the Minister of Health, Labor and Welfare Award | |

| 2010 | Yokokawa Manufacturing Plant | Gunma Prefecture food voluntary hygiene management certification acquired | |

| 2010 | Suwa Manufacturing Plant | Received the Minister of Health, Labor and Welfare Award | |

| 2014 | Nagano Store | Certified as a 5-star restaurant for food safety and security by the Japan Food Sanitation Association | |

| 2018 | Suwa Branch | Nagano Food Sanitation Association Suwa Branch certified as a 5-star restaurant for food safety and security |